When Associate Professor Prateek Sharma was acknowledged with the Samuel Cate Prescott Outstanding Young Scientist Award from the Institute of Food Technologists (IFT), a global society of meals scientists, his division head, Professor Heidi Wengreen, was proud however not stunned.

“Prateek has a genuine excitement for learning and discovery in dairy science,” she stated. “He cares deeply about the structure of cheese because he knows it matters to the dairy industry and to anyone who simply wants their cheese to taste great and melt just right. He creates meaningful research opportunities for students and takes pride in mentoring the next generation of dairy scientists. We are so proud to see his passion and hard work recognized with this award.”

The award is given to 1 meals scientist every year who has made vital contributions to the sphere inside a decade of achieving their highest educational diploma. Sharma acquired it at IFT First, the world’s largest meals science and innovation expo earlier this yr.

Sharma’s analysis focuses on enhancing the standard of dairy meals by means of a mixture of chemistry, physics, engineering and a touch of microbiology.

“More than 50 percent of my research is in the area of cheese processing, chemistry and technology with the remaining percent in areas like fluid milk, dairy powders and whey,” Sharma stated. “What I try to do is use the principles of material science to improve the quality of dairy products and the efficiency of dairy processing operations.”

When requested to supply examples of his work, Sharma is delighted to produce them. He has co-authored quite a few papers on mozzarella alone, and he can communicate at size about how the formation and destruction of chemical bonds interprets into the meltability and stretchability of cheese on a slice of pizza or the exact mixture of warmth, protein, sugar, moisture and useful micro organism wanted to realize a Maillard response and the right degree of browning.

His analysis additionally has quite a few sensible functions for the meals business. For occasion, when cheddar cheese is mass produced, it typically is available in large blocks weighing a whole lot of kilos which can be then processed in several methods to make slices, shreds and cubes. However, the bodily properties of a selected block of cheese have an effect on how nicely it might deal with passing by means of machines that remodel it into merchandise shoppers are acquainted with. Cheese that’s notably sticky or fragile can result in gummed up equipment and a lack of product, so there’s appreciable cash to be saved if producers can establish the properties of cheese early on.

“Slicing is a premium product, so if cheese is really good for that, then businesses would like to make slices first,” Sharma stated. “If it’s not good enough for slicing, then the second preferred operation is shredding. And if cheese isn’t suitable for either of those operations, then it gets processed into other products, which is a low-value application. If I’m able to develop a predictive model for the cheese, manufacturers can determine beforehand what should be done with a block to save time and reduce material loss.”

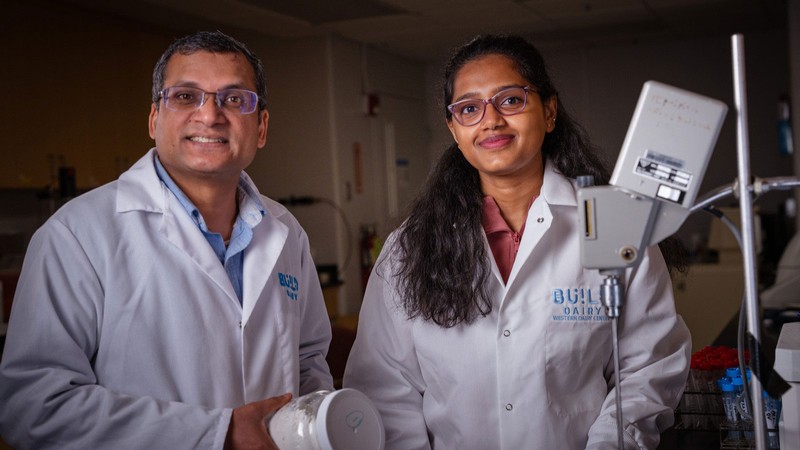

In addition to his personal analysis, Sharma has additionally just lately taken on a brand new function: director of the Western Dairy Center (WDC), a community of 9 universities in Utah, Idaho, Oregon and Washington. With help from Dairy West and the Dairy Checkoff Program, WDC coordinates dairy analysis, supplies the dairy business with entry to school researchers and assets, provides programs on topics like small-scale cheese or ice cream manufacturing to entrepreneurs and hobbyists, and facilitates the Build Dairy program. The latter helps educate the subsequent era of researchers to satisfy the present and future calls for of the dairy business, Sharma stated.

“Build Dairy connects professors, students and businesses together to identify real issues in the dairy industry,” he stated. “For instance, a professor might develop a project proposal to solve a problem in consultation with the dairy industry and identify a student who then works on that problem. It’s student-centric training that facilitates research while also providing the industry with highly skilled scientists in the Intermountain region.”

Sharma devoted his award to the individuals and organizations who helped him achieve his analysis and his function as director of the WDC.

“I’d like to thank my students as well as my mentors and role models, including Professor Peter Munro (formerly of Massey University), Professor Emeritus E. Allen Foegeding (North Carolina State University), Professor Donald McMahon (formerly of Utah State), and Dr. Eric Bastian (vice president for Dairy West) for their support and guidance, as well as the USDA-NIFA, DMI, BUILD, NSF Convergence Accelerator, U.S. Department of Energy, USU, and other organizations who supported my research program at USU. And last but not least, I would like to thank my family, including my parents, brother Yogesh Sharma, my wife Bharti, son Pratham, and daughter Prabha for their patience and support throughout my scientific journey.”