How do you stop biofilms — massive communities of micro organism just like the slime on your enamel earlier than you sweep — from rising in water programs in space and on Earth?

A multi-university analysis crew led by Arizona State University Regents Professor Paul Westerhoff is investigating ultraviolet gentle as a cheap, safer different to disinfecting chemical compounds to forestall biofilm development on surfaces, thus lowering well being dangers and gear injury.

The crew’s National Science Foundation-funded Germicidal Ultraviolet Light Biofilm Inhibition, or GULBI, experiment was one of many 15 tasks launched on NASA’s Northrop Grumman Commercial Resupply Services 23 mission to the International Space Station on Sept. 14.

In the humid space station, stopping biofilm is important as a result of “anywhere there is any moisture, biofilms will grow on surfaces,” says Westerhoff, who develops novel applied sciences to deal with rising water points on the School of Sustainable Engineering and the Built Environment, a part of the Ira A. Fulton Schools of Engineering at ASU.

“On Earth, biofilms cause an estimated $4 trillion in damage every year because they corrode metals, promote mold on surfaces, harbor harmful pathogens in medical devices such as catheters and increase energy consumption in heat exchangers,” Westerhoff says. “Biofilms in crustaceans attached to boats are responsible for over 10% of their energy or diesel costs.”

Why use ultraviolet gentle?

Westerhoff’s crew noticed how germicidal ultraviolet gentle, or UV-C, broke bonds in bacterial DNA, prevented repairs and inhibited biofilm development.

Partnering with NASA, his startup firm H2Optic Insights developed UV-C side-emitting optic fiber that proved efficient at controlling development of the micro organism that causes Legionnaires’ disease in cooling tower constructions that use water and a fan to sit back air in buildings.

They questioned if this know-how may work successfully in space’s microgravity and scale back the necessity for disinfecting chemical compounds?

That query turned particularly related given the excessive price of sending even fundamental provides to the ISS — with one estimate placing a 500 milliliter bottle of disinfectant at $20,000 or extra, says Robert McLean, a Texas State University Regents Professor who focuses on biofilms and is a part of GULBI’s multi-university crew.

On the ISS, wastewater is collected, purified by distillation, handled, disinfected and reused as consuming water, says McLean, noting wastewater biofilms are proof against normal disinfectants.

“In the past, some tubing on the ISS located before the treatment steps became clogged with biofilms and needed to be replaced,” McLean says. “While such emergency measures can be done on the ISS, travel to the moon or even Mars does not allow for replacement items to be sent from Earth or crew evacuation in an extreme situation.”

Experiment particulars

The GULBI experiment compares how biofilm from the micro organism Pseudomonas aeruginosa grows in space’s microgravity versus on Earth when handled with UV-C gentle delivered via skinny, versatile, side-emitting optical fibers.

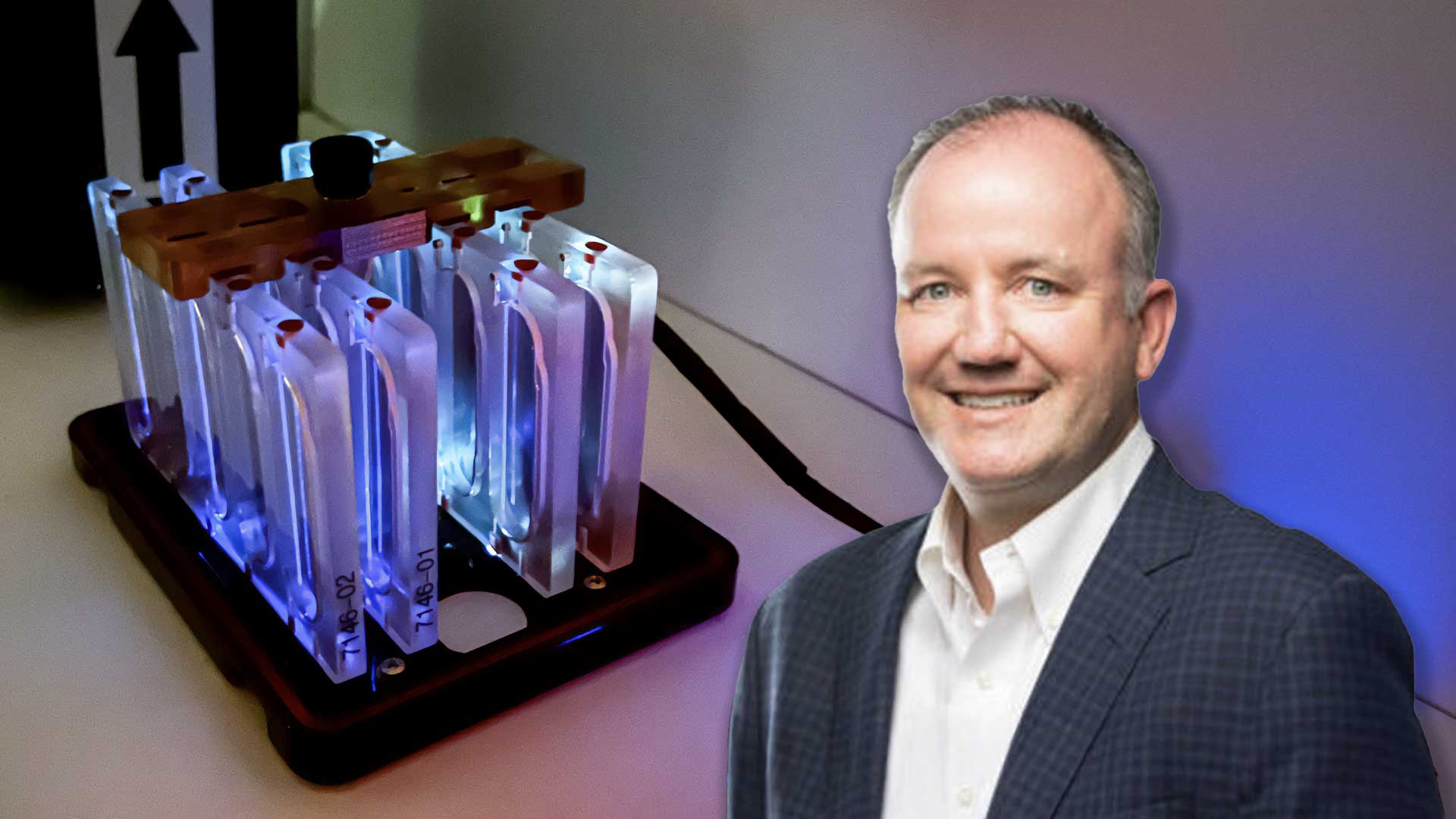

The setup contains 16 small models referred to as BioCells, every containing 5 pattern wells. Built by implementation accomplice BioServe Space Technologies, these BioCells maintain liquid nutrient media, micro organism and metallic surfaces inside a plate habitat, or PHAB, related to a management field that powers the LED gentle sources and cooling system.

BioServe additionally designed the flight {hardware} and dealt with all of the mission integration steps required to get the GULBI experiment onboard the ISS, says Stefanie Countryman, director of the middle inside the University of Colorado Boulder’s Ann and H.J. Smead Department of Aerospace Engineering Sciences.

The group has designed, constructed and flown a whole lot of microgravity life science analysis experiments and spaceflight-certified {hardware} on greater than 110 missions.

On the third, ninth, fifteenth and twenty first day of the experiment, astronauts take away one PHAB from storage and place it in the Life Science Glovebox, Westerhoff says.

“(These plate habitats) are individual packages the astronauts take out,” Westerhoff defined throughout the Northrop Grumman CRS-23 Pre-Launch Science Webinar hosted by the International Space Station National Laboratory. “They’ll (inoculate the) BioCells, close them back up and essentially (allow the bacteria) to incubate over time.”

The samples are then uncovered to steady, intermittent or no UV-C gentle. Later, crew members accumulate bacterial samples, inject fixatives and place BioCells in temperature-controlled storage till they return to Earth.

“This is the first time (that) hardware was designed and spaceflight-certified (using) the science team’s UV-C side-emitting fibers to limit or eliminate biofilm formation in a microgravity environment,” Countryman says.

McLean’s crew helped plan the science and evaluation for the GULBI experiment with Westerhoff and ASU School of Life Sciences Professor Cheryl Nickerson.

“We developed a rapid, molecular-based test to measure individual population levels of a multi-species biofilm to see if any antimicrobial effect showed a preference for a small number of species or was universal in nature,” McLean says.

Nickerson’s crew has flown 12 life sciences and well being experiments to the International Space Station.

“We have more than 20 years of experience in space biomedical research to protect astronaut health and sustainability of their spacecraft, which includes onboard life support systems like drinking water,” says Nickerson, who focuses on dynamic interactions between microorganisms, their surroundings and contaminated hosts in space and Earth.

Her crew — together with analysis assistant professors Jennifer Barrila, a co-principal investigator on this research, and Jiseon Yang, with the ASU Biodesign Center for Fundamental and Applied Microbiomics — ready the organic science in time for the mission’s launch date and educated different crew members to allow high-quality analysis in space, together with doctoral scholar Ken Niimi on Westerhoff’s crew.

Barrila, Yang and Niimi did in depth lab work and gadget fabrication over two years to prepare for this uncommon alternative to carry out experiments in microgravity, Westerhoff says.

“Our extensive experience in pre-flight optimization of the biology, preparation and handover of the experiment for launch, as well as the design of ground-based controls, were valuable for this effort since doing biological research in space is nothing like doing it in Earth-based laboratories,” Nickerson says.

What’s subsequent

The crew expects to study from GULBI the influence UV-C has on the quantity and construction of biofilm development in space, since “our collaborators’ previous work shows the structures of biofilms in microgravity are very different than on Earth,” Westerhoff says.

Non-chemical strategies like GULBI to cut back biofilms the place moisture is discovered are important.

“If we’re going to live or manufacture in space, we’re going to need water,” Westerhoff says.

UV gentle reduces the necessity to haul extra silver or iodine disinfecting chemical compounds to the orbiting lab and modify surfaces with totally different coatings, he says, noting it’s already in a conveyable water dispenser system on ISS to eradicate viruses earlier than astronauts drink.

This summer season, Westerhoff’s crew and NASA began a Phase III utility that put a mesh of H2Optic Insights’ side-emitting optical fibers right into a water bellows tank designed for the ISS.

“By studying how biofilms behave in extreme environments like microgravity, we can improve both our fundamental understanding and our ability to prevent their widespread problems here on Earth,” he says.