A analysis group at Rice University, working with worldwide collaborators, has created the primary environmentally pleasant technology that may shortly entice and break down poisonous “forever chemicals” (PFAS) in water. The outcomes, revealed just lately in Advanced Materials, characterize a significant advance towards one of the vital cussed air pollution threats worldwide.

The mission was led by Youngkun Chung, a postdoctoral fellow mentored by Michael S. Wong, a professor at Rice’s George R. Brown School of Engineering and Computing. The effort additionally included Seoktae Kang, a professor on the Korea Advanced Institute of Science and Technology (KAIST), and Keon-Ham Kim, a professor at Pukyung National University in South Korea.

What Are PFAS and Why Are They a Problem

PFAS, brief for per- and polyfluoroalkyl substances, are man-made chemical substances that date again to the Nineteen Forties. They have been utilized in many on a regular basis merchandise, together with Teflon pans, waterproof clothes, and some meals packaging. PFAS turned well-liked as a result of they resist warmth, grease, and water, however that very same sturdiness additionally means they break down very slowly, which is why they’re usually known as “forever chemicals.”

PFAS have now unfold extensively and may be present in water, soil, and air around the globe. Research has linked publicity to liver injury, reproductive problems, immune system disruption, and sure cancers. Cleanup has been tough as a result of as soon as PFAS enter the setting, they’re exhausting to take away and even more durable to destroy.

Why Current PFAS Removal Methods Fall Short

Many normal approaches depend on adsorption, which means the chemical substances persist with supplies reminiscent of activated carbon or ion-exchange resins. These strategies are frequent, however they’ve main limitations, together with low efficiency, sluggish operation, restricted capability, and the buildup of extra contaminated waste that also needs to be dealt with.

“Current methods for PFAS removal are too slow, inefficient and create secondary waste,” mentioned Wong, the Tina and Sunit Patel Professor in Molecular Nanotechnology and professor of chemical and biomolecular engineering, chemistry and civil and environmental engineering. “Our new approach offers a sustainable and highly effective alternative.”

The Breakthrough LDH Material That Works Fast

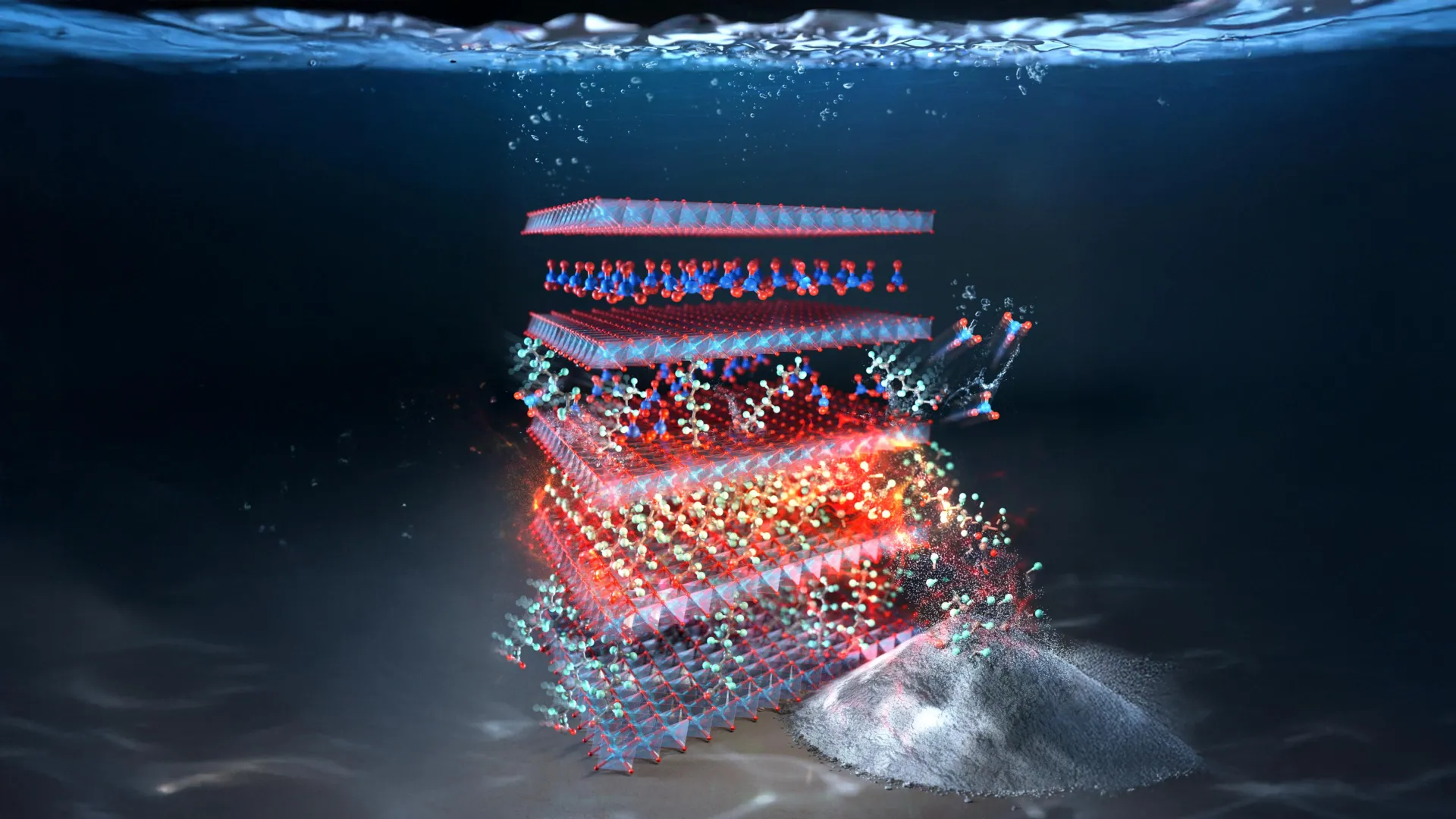

The new method is constructed round a layered double hydroxide (LDH) materials comprised of copper and aluminum. Kim first recognized any such materials whereas he was a graduate pupil at KAIST in 2021. As the group explored these compounds additional, Chung discovered {that a} particular model containing nitrate might adsorb PFAS with unusually excessive efficiency.

“To my astonishment, this LDH compound captured PFAS more than 1,000 times better than other materials,” mentioned Chung, a lead creator of the research and now a fellow at Rice’s WaTER (Water Technologies, Entrepreneurship and Research) Institute and Sustainability Institute. “It also worked incredibly fast, removing large amounts of PFAS within minutes, about 100 times faster than commercial carbon filters.”

Researchers say the spectacular outcomes come from the fabric’s inside design. Its ordered copper-aluminum layers, alongside with small cost imbalances, create a extremely favorable floor the place PFAS molecules can connect shortly and strongly.

Tested in River Water, Tap Water, and Wastewater

To see how effectively the system might carry out outdoors the lab, the group examined the LDH materials in river water, faucet water, and wastewater. Across all three, it remained extremely efficient. It additionally carried out effectively in each static checks and continuous-flow setups, pointing to attainable use in municipal water remedy methods and industrial cleanup.

Closing the Loop With PFAS Destruction and Reuse

Capturing PFAS is barely half the battle for the reason that chemical substances nonetheless must be destroyed safely. Working with Rice professors Pedro Alvarez and James Tour, Chung developed a course of to thermally decompose PFAS after they’re captured on the LDH materials. When the PFAS-loaded materials was heated with calcium carbonate, the researchers eliminated greater than half of the trapped PFAS with out releasing poisonous by-products. The similar step additionally regenerated the LDH, making it attainable to make use of the fabric once more.

Early testing confirmed the fabric might undergo no less than six full cycles of seize, destruction, and renewal. That makes it the primary recognized eco-friendly, sustainable system for PFAS removing that mixes speedy cleanup with repeated reuse.

International Collaboration and Research Support

“We are excited by the potential of this one-of-a-kind LDH-based technology to transform how PFAS-contaminated water sources are treated in the near future,” Wong mentioned. “It’s the result of an extraordinary international collaboration and the creativity of young researchers.”

A listing of all of the researchers concerned on this research and their institutional affiliations may be discovered right here. This analysis was supported by the Basic Science Research Program via the National Research Foundation of Korea funded by the Ministry of Education (2021R1A6A3A14044449, RS-2023-00242795), grants from the National Convergence Research of Scientific Challenges and the Sejong Science Fellowship via the National Research Foundation of Korea and funding from the Ministry of Science (NRF-2022M3C1C8094245) and ICT (RS-2024-00395438). This work was additionally funded by Saudi Aramco-KAIST CO2 Management, Nanosystems Engineering Research Center for Nanotechnology-Enabled Water Treatment (NEWT), the U.S. Army Corps of Engineers’ Engineering Research and Development Center grant (W912HZ-21-2-0050), Rice Sustainability Institute and Rice WaTER Institute.