1. a. Which rising science and expertise areas (e.g., synthetic intelligence) shall be key to the subsequent era of modern superior manufacturing applied sciences, and how will they impression superior manufacturing?

A large suite of digital manufacturing applied sciences—together with synthetic intelligence (AI) (and particular person AI functions akin to AR/VR, pc imaginative and prescient, professional programs, digital twins, and robotic course of automation), large information, cloud computing, the Internet of Things, sensors, robots/cobots, superior wi-fi communications, and computer-aided design (CAD) and engineering (CAE) software program—instruments are poised to remodel fashionable manufacturing. In reality, digital companies now account for 25 p.c of manufacturing inputs.[1] And digital inputs account for 40 p.c of the worth of a fashionable automobile.[2]

The software of digital manufacturing applied sciences shall be important. Analysts anticipate manufacturing digitalization to increase general international manufacturing unit productiveness up to 25 p.c.[3] One evaluation finds manufacturing digitalization might produce a 10 p.c enchancment in general working effectivity; 25 p.c enchancment in vitality effectivity; 25 p.c discount in client packaging; 25 p.c discount in security accidents; 40 p.c discount in cycle instances; and 40 p.c discount in water utilization.[4] Overall, economists estimate manufacturing digitalization might increase annual U.S. productiveness progress by 1 to 1.5 share factors and add $10 to $15 trillion to international GDP over the subsequent 20 years.[5]

Manufacturers stand at differing ranges of implementing sensible manufacturing options. One March 2025 examine of over 800 massive multinational producers discovered that 98 p.c have not less than initiated digital transformation efforts looking for to enhance their buyer expertise and operational effectivity, optimize prices, or improve merchandise.[6] However, implementation of digital manufacturing options is decidedly decrease amongst small- to medium-sized (SME) producers. A 2024 survey performed by the Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) at Auburn University discovered that 56 p.c of U.S. SME producers have been both at present utilizing or now implementing automation instruments and 49 p.c utilizing additive manufacturing, however that solely 38 p.c have been utilizing large information, solely 28 p.c AI, and solely 27 p.c information analytics.[7]

The United States considerably trails within the deployment of robotics—a cross-cutting automation instrument that shall be very important to the competitiveness of myriad U.S. manufacturing industries. In reality, China has put in extra industrial robots than the remaining of the world mixed in every of the previous 5 years. When nations are assessed by their deployment of industrial robots per 10,000 employees, the United States ranks tenth, whereas China ranks third.[8] The United States wants to considerably scale up its deployment of industrial robots, and ITIF laid out a technique to achieve this in its current report “A Time to Act: Policies to Strengthen the US Robotics Industry.” Several suggestions which stood out from the report embrace that the United States ought to develop a nationwide technique for robotics, the Department of Commerce ought to convene a robotics {industry} advisory group to advise the U.S. authorities on robotics {industry} wants and how to enhance adoption and procurement, and the United States ought to develop its investments in commercially oriented robotics analysis and improvement (R&D).[9] Further, president Trump ought to problem an annual award on the White House to companies which have completed the most effective job of putting in robots, and use his bully pulpit to disgrace different executives who’ve gone capital-light and failed to spend money on automation.[10]

1. b. What are the first challenges and limitations that want to be addressed to make sure the profitable integration and widespread adoption of rising expertise in manufacturing?

A litany of provide and demand challenges proceed to inhibit the broader adoption of rising applied sciences in U.S. manufacturing. One problem is that the applied sciences are nonetheless evolving and not but absolutely mature. As Industry Week’s Jessica Davis notes, “Implementing an Internet of Things program isn’t exactly like flipping a switch. There’s a lot involved, from sensors where the data is initially collected to the network the data travels, to the analytics systems that figure out what it all means.”[11] An absence of interoperable requirements between vendor options represents one other important problem. As the report “Industrie 4.0 in a Global Context: Strategies for Cooperating with International Partners” explains, “individual modules, components, devices, production lines, robots, machines, sensors, catalogues, directories, systems, databases, and applications will need common standards for the connections among them and for the overall semantics, or how data gets seamlessly passed from one device to another.”[12] Thus, standardization of architectures, data-exchange codecs, vocabularies, taxonomies, ontologies, and interfaces shall be key to creating interoperability between completely different digital manufacturing options, and the U.S. National Institute of Standards (NIST) can play an essential position in facilitating this.

Recent analysis from the Boston Consulting Group and McKinsey has discovered that 70 p.c of digital transformation initiatives fail to meet their targets.[13] A major motive why pertains to lagging worker abilities and competencies to successfully implement digital options and to a lack of readability relating to the worth proposition behind digital implementations. This is why many international locations stock and describe discrete, particular manufacturing digitalization use circumstances and processes. For instance, Germany has documented over 300 particular use circumstances/pattern instantiations of SME manufacturing digitalization.[14] Further, as the next part on small producers will doc, they typically lack the capital to spend money on modernized plant and gear.

A second problem is that too many U.S. firms search to go “asset light,” limiting funding in capital property to make their stability sheets extra favorable to traders. It is past the scope of this submission to deal with this problem, however a job pressure led by Treasury and together with different main monetary companies, together with the Securities and Exchange Commission and banking regulators, ought to search options to this.

2. a. Which disruptive manufacturing applied sciences (e.g., additive, nanotechnology, biotechnology) maintain the potential to remove reliance on international sources for important minerals and supplies, and how will they try this?

b. What are the technical challenges and limitations related to implementing these applied sciences at an industrial scale, and how can they be addressed?

The United States should make it a nationwide crucial to lower dependence on China for key important minerals. For occasion, for uncommon earths utilized in magnets—notably neodymium, praseodymium, dysprosium, and terbium—China accounted for about 60 p.c of their international mining and 90 p.c of their refining and processing in 2024.[15] Overall, China accounts for round 60 p.c of the worldwide provide of battery-grade lithium, 65 p.c of nickel, 70 p.c of cobalt, and 90 p.c of rare-earth parts akin to neodymium.[16] China can be the first international provider for many key lively pharmaceutical components (APIs). For occasion, roughly 70 p.c of the world’s paracetamol (acetaminophen) originates from Chinese companies and over 80 p.c of key antibiotic actives (e.g., doxycycline and amoxicillin) are produced in China.[17]

The solely method the United States can restore its capacities in important mineral/uncommon earths processing and refining in a method that’s cost-competitive with Chinese manufacturing whereas nonetheless being environmentally pleasant is thru innovation. This would require novel, modern, new-to-the-world refining processes to deal with China’s lead on this subject. This would require ample R&D funding from each the general public and personal sectors and additionally the funding of Ph.D. researchers to develop these new processes. As such, the United States ought to set up a new National Science Foundation (NSF) Engineering Research Center (ERC) for important minerals refining and processing.

4. a. What are examples of U.S. manufacturing-related technological, market, or enterprise challenges which will finest be addressed by public-private partnerships and are doubtless to entice each participation and main funding from {industry}?

b. How can public-private partnerships be structured to overcome potential hurdles and foster profitable collaboration?

The Fraunhofer-Gesellschaft represents Europe’s largest application-oriented analysis group, comprised of 67 institutes. One of the traditionally nice strengths of Germany’s Fraunhofer system is that it brings German {industry} and academia collectively in a structured method to develop new applied sciences with particular industrial relevance.[18] Each Fraunhofer is co-led by a consultant from {industry} and academia. The Fraunhofers work with particular German industrial sectors to develop 10-year expertise roadmaps for {industry}, figuring out particular technical hurdles or challenges that want to be addressed, and then by means of the related universities they fund Ph.D.s to resolve these technological issues and then diffuse that information again all through Germany’s industrial ecosystem. The German authorities on the federal and state ranges co-invest within the effort, protecting about 30 p.c of program prices.

America’s Manufacturing USA community is considerably modeled after this method. But what it actually factors to is that the United States needs to be growing manufacturing-sector-specific competitiveness and innovation methods. The semiconductor {industry} has lengthy completed this effectively, and even now the Semiconductor Research Corporation (SRC) has articulated a Decadal Plan for Semiconductors, which has outlined particular analysis challenges akin to vitality administration, storage density, security-on-chip, and so forth.[19] Similarly, ITIF has known as for the Trump administration to encourage the creation of the biopharma equal of the SRC.[20] Here, {industry} might collaborate on such a manufacturing expertise innovation roadmap, and the federal authorities might match their funding to analysis institutes and universities on a dollar-for-dollar foundation. For instance, some life-sciences companies have their very own roadmaps (e.g., GlaxoSmithKline’s manufacturing expertise roadmap is targeted on the use of steady methods).[21]

Beyond biotechnology and semiconductors, the United States needs to be growing related decadal competitiveness methods/expertise roadmaps for key manufacturing industries together with aerospace, automotive, chemical compounds, robotics, machine instruments, shipbuilding, and so forth. The U.S. authorities needs to be a associate with American academia and {industry} in serving to develop these methods, however sadly it lacks not simply the assets but in addition the important thing information to undertake the analytics vital. For this motive, ITIF has laid out a complete evaluation of what are the federal statistical wants that may underpin a complete “National Advanced Industry and Technology Strategy.”[22]

Ensuring that small producers can faucet into the technological experience being developed by the Manufacturing USA Institutes is essential. A following part mentioned bettering Manufacturing USA/Manufacturing Extension Partnership (MEP) coordination. While every of the Manufacturing USA Institutes have completely different enterprise fashions/worth propositions, some have created distinctive pathways for SMEs to interact with them, akin to how MxD (targeted on digital manufacturing) supplied $500 subscriptions for a low-tier set of outputs. Each Manufacturing USA Institute ought to have an SME engagement technique.

5. a. How can Federal companies and federally funded R&D facilities supporting superior manufacturing R&D facilitate the switch of analysis outcomes, mental property, and expertise scale-up into commercialization and manufacturing.

5.b. What are the important thing challenges in translating analysis findings into commercially viable manufacturing processes and merchandise, and how can they be overcome?

First and foremost, America wants to undertake and keep a supportive, and non-disruptive, method to the efficient expertise and mental property (IP) switch system the United States has already developed, and to the extent it reforms this method it ought to deal with value-adding enhancements on the margins. The administration also needs to acknowledge that the method of IP/expertise commercialization is already dangerous, tough, costly, and fraught with many valleys of demise.

The Trump administration ought to additional acknowledge that the United States has already constructed the world’s simplest system for expertise commercialization, particularly when it pertains to IP/applied sciences derived from federally funded R&D performed at U.S. universities and analysis establishments. However, as late as 1978, the federal authorities had licensed lower than 5 p.c of the as many as 30,000 patents it owned.[23] Most of them languished on the cabinets of authorities workplaces or labs. Congress remodeled the scenario by passing the bipartisan 1980 Patent and Trademark Law Amendments Act, higher generally known as the “Bayh-Dole Act.” The laws each created a uniform patent coverage among the many many federal companies funding analysis and allowed universities to retain possession of the IP and innovations made as a end result of federally funded analysis.[24] The Bayh-Dole Act has remodeled U.S. universities into engines of innovation, spawning sturdy tutorial expertise switch and commercialization capabilities and actions at a whole bunch of universities throughout the United States which have led to the launch of over 18,000 start-up firms.[25]

The Trump administration ought to focus first on preserving the efficient operation of the Bayh-Dole framework. When Congress handed the Bayh-Dole Act it included so-called “march-in right” provisions, which enable the federal government, in specified circumstances, to require patent holders to grant a “nonexclusive, partially exclusive, or exclusive license” to a “responsible applicant or applicants.”[26]

The Bayh-Dole Act specifies solely 4 situations during which the federal government is permitted to train march-in rights, and cheap costs isn’t one. Yet some have known as for the federal government to use Bayh-Dole march-in rights to management the worth of ensuing merchandise, akin to pharmaceutical medicine. This even if decrease costs usually are not one of the rationales specified by the Bayh-Dole Act. In reality, as senators Bayh and Dole have themselves famous, the Bayh-Dole Act’s march-in rights have been by no means supposed to management or guarantee “reasonable prices.”[27] As the senators wrote in a 2002 Washington Post op-ed titled, “Our Law Helps Patients Get New Drugs Sooner,” the Bayh-Dole Act: “Did not intend that government set prices on resulting products. The law makes no reference to a reasonable price that should be dictated by the government. This omission was intentional.”[28]

The Trump administration ought to return to an initiative undertaken in its first iteration, when it had directed NIST to undertake a evaluate of federal insurance policies that would bolster the return of federal investments in R&D. The closing 2018 report NIST produced, the “Return on Investment Initiative: Draft Green Paper,” concluded, “The use of march-in is typically regarded as a last resort, and has never been exercised since the passage of the Bayh-Dole Act in 1980.”[29] The report additional famous, “NIH determined that that use of march-in to control drug prices was not within the scope and intent of the authority.”[30] The Trump administration ought to construct upon the findings of the 2018 NIST Green Paper and affirmatively declare that worth just isn’t a official foundation for the train of Bayh-Dole march-in rights.

As ITIF has argued, the most important issue for Bayh-Dole licensees to manufacture within the United States has been the evisceration of America’s manufacturing base has denuded their potential to discover manufacturing choices within the United States—and so the easiest way to cope with this problem is by completely revitalizing American manufacturing, as this RFI helps search to accomplish. The laws does embrace some helpful proposals, together with directing NIST to determine and keep a database of home producers that commercialize merchandise and companies developed from federally funded analysis. The invoice would additionally require NIST to report to Congress on the commercialization of federal analysis by home producers inside 18 months (of the invoice’s passage).[31] One enchancment ITIF has known as for the laws to make (and for NIST to implement) is for the U.S. authorities to develop a related database of producers in key allied nations; which might make it simpler for licensees to determine alternative-to-China producers when choices are unavailable within the United States.

As famous, a important energy of the U.S. innovation system is that it has turned America’s universities into engines of innovation, thanks largely to the Bayh-Dole Act. In reality, the impression of tutorial expertise switch from U.S. universities has been so intensive that, from 1996 to 2020, it resulted in 554,000 innovations disclosed, 141,000 U.S. patents granted, and 18,000 start-ups shaped.[32] Moreover, tutorial expertise switch has bolstered U.S. gross home product (GDP) by up to $1 trillion, contributed to $1.9 trillion in gross U.S. industrial output, and supported 6.5 million jobs over that point.[33]

In September 2025, in an Axios interview, Commerce Secretary Howard Lutnick known as for the federal authorities to declare half the patent earnings from college innovations derived partly from federal R&D, erroneously asserting that “the U.S. government is getting no return on the money it invests in federal research.”[34] Yet the fact is the U.S. taxpayer—and the federal government—advantages vastly from this R&D funding. They profit first from the intensive improvements produced from the educational tech switch course of, which alone has produced a whole bunch of life-saving medicine and vaccines, together with therapies for breast, ovarian, prostate, and pores and skin most cancers, not to point out different breakthroughs in every part from Honeycrisp apples and neoprene to cloud and quantum computing. Second, college IP licensing revenues assist fund key innovation-enabling infrastructure at U.S. universities, akin to labs, incubators, or innovation accelerators that hold the innovation flywheel churning. Third, the federal government advantages from the taxes produced by the trillions in industrial output and hundreds of thousands of jobs created as a end result of college tech switch.[35] For occasion, college analysis parks alone generated $33 billion in federal tax income in 2024.[36] The administration ought to chorus from imposing a declare or a tax on IP licensing revenues earned by U.S. universities.

6.a. What are the primary challenges in attracting, coaching, and retraining a expert workforce for superior manufacturing, and how can they be addressed?

If the United States is to obtain its ambition to considerably revitalize American manufacturing, it wants to take additional steps to make sure that it possesses the manufacturing workforce to help expanded U.S. manufacturing output. That’s particularly the case as analysts anticipate the demand for tech expertise to develop to 7.1 million tech jobs by 2034 within the United States, from an estimated six million in 2023.[37] Another report by the Semiconductor Industry Association (SIA) finds that, by the tip of 2030, an estimated 3.85 million extra jobs requiring proficiency in technical fields shall be created within the United States, however that, “Of those, 1.4 million jobs risk going unfilled unless we can expand the pipeline for such workers in fields such as skilled technicians, engineering, and computer science.”[38] For the semiconductor {industry}, the report estimates that roughly 67,000—or 58 p.c of projected new jobs (and 80 p.c of projected new technical jobs)—threat going unfilled at present diploma completion charges.[39] The administration ought to lead in a number of efforts to improve U.S. manufacturing workforce skilling, together with:

Expand Advanced Technological Education (ATE) program funding. Skilled technicians are a key element of the traded sector workforce. One extremely profitable program designed to construct technician abilities is NSF’s Advanced Technological Education program, which helps neighborhood faculties working in partnership with {industry}, financial improvement companies, workforce funding boards, and secondary and different greater schooling establishments.[40] ATE tasks and facilities are educating technicians in a vary of fields, together with nanotechnologies and microtechnologies, fast prototyping, biomanufacturing, logistics, and different gas cars. Notwithstanding this, ATE funding is kind of small, at roughly $74 million in FY 2025.[41] The Trump administration ought to work with Congress to double ATE funding to not less than $150 million per yr.

Expand the Manufacturing Engineering Education Program (MEEP). The engineering curricula at too many American universities is overly tutorial as opposed to {industry} targeted. Indeed, college engineering applications have developed in two troubling instructions over the previous a number of a long time. First, the deal with “engineering as a science” has more and more moved college engineering schooling away from a deal with actual drawback fixing towards extra summary engineering science. Second, this deal with “engineering as a science” has left college engineering departments extra involved with producing pure information than working with {industry} to assist them resolve actual issues.

That’s why ITIF has argued that the United States wants extra “manufacturing universities,” which might revamp their engineering applications and focus far more on manufacturing engineering and specifically work that’s extra related to {industry}. This would come with extra joint industry-university analysis tasks, extra scholar coaching that includes manufacturing experiences by means of co-ops or different applications, and a Ph.D. schooling program targeted on turning out extra engineering graduates who work in {industry}. These universities would view Ph.D.s as akin to high-level apprenticeships (as they typically are in Germany), the place {industry} expertise is required as half of the diploma. Likewise, standards for school tenure would take into account professors’ work with and/or in {industry} as a lot as their quantity of scholarly publications. In addition, these universities’ enterprise faculties would combine intently with engineering and deal with manufacturing points, together with administration of manufacturing.

One mannequin for these manufacturing universities is the Olin College of Engineering in Massachusetts, which reimagined engineering schooling and curriculum to put together college students “to become exemplary engineering innovators who recognize needs, design solutions, and engage in creative enterprises for the good of the world.”[42]

Congress carried out a kind of these proposals when it handed the Manufacturing Engineering Education Program into regulation in December 2016 as half of the 2017 National Defense Authorization Act (NDAA), authorizing the Department of Defense to help industry-relevant, manufacturing-focused, engineering coaching at U.S. establishments of greater schooling, universities, {industry}, and not-for-profit establishments. With its $48 million in preliminary funding, MEEP made awards to 13 instructional and {industry} companions to convey instructional alternatives to Americans curious about studying manufacturing abilities important to sustaining the U.S. protection innovation base.[43] In 2023, MEEP issued extra three-year funding grants “that establish programs or enhance existing programs to better position the manufacturing workforce to produce military systems and components that assure technological superiority for DoD.”[44]

MEEP will be a highly effective initiative, however it’s underfunded and has grow to be too solely targeted on engineering within the nationwide protection context. Therefore, the Administration ought to work with Congress to broaden the MEEP remit to refocus it extra on supporting industry-relevant, utilized engineering applications at main universities. Congress ought to allocate $150 million yearly to a revitalized MEEP program that may make grants to 20 engineering applications at main U.S. universities to redirect them towards extra hands-on, industrially related engineering actions.

6.b. How can Federal companies and federally funded R&D facilities develop, align, and strengthen all ranges of superior manufacturing coaching, certification, registered apprenticeships, and credentialing applications.

Each Manufacturing USA Institute ought to develop workforce coaching workstreams related to their focal expertise space. For occasion, MxD’s “Digital Manufacturing and Design Roles Taxonomy” recognized 165 distinct digital manufacturing and design roles, describing the obligations of every of these roles and the talents people wanted to accrue to fulfill them.[45] Beyond figuring out new roles and occupations, every of the Manufacturing USA Institutes ought to work with their affiliated tutorial companions to construct and ship instructional curricula for these positions.

The National Skill Standards Act of 1994 created a National Skill Standards Board (NSSB) accountable for supporting voluntary partnerships in every financial sector that may set up industry-defined nationwide requirements main to industry-recognized, nationally transportable certifications. But this imaginative and prescient has but to be fulfilled. Therefore, Congress and the Administration ought to work to enhance credentialing for the manufacturing and the intently associated logistics {industry} workforce members by increasing the use of standards-based, nationally transportable, industry-recognized certifications particularly designed for particular manufacturing and logistics sectors.[46]

The United States considerably underinvests in workforce coaching applications, dedicating simply 0.1 p.c of GDP in lively labor market applications in contrast with the Organization for Economic Cooperation and Development (OECD) common of 0.6 p.c of GDP, which means America’s OECD friends akin to Austria and Germany make investments six or extra instances extra of their workforce coaching and help applications.[47] Moreover, the United States now invests lower than half of what it did in such applications 30 years in the past, as a share of GDP.[48]

One method the Trump administration and Congress might deal with this problem can be by increasing Section 127 tax advantages for employer-provided tuition help. Section 127 of the federal tax code permits employers to present workers up to $5,250 per yr in tuition help; the employer deducts the price of the profit however the worker doesn’t have to report it as revenue.[49] Congress ought to enhance Section 127 to not less than $8,700 (per the speed of inflation since 1996) and index the quantity to the annual charge of inflation going ahead.[50]

7. a. In what methods can the federal authorities help within the improvement of superior manufacturing clusters and expertise hubs nationwide, past funding wants?

b. Is there a want for new or expanded superior manufacturing clusters or expertise hubs for the competitiveness of U.S. producers, and if that’s the case, in what sectors or applied sciences?

c. Should Federal incentives prioritize industry-specific superior manufacturing clusters or as an alternative deal with expertise hubs centered on superior applied sciences, important elements, and supplies? If so, why?

In a 2019 report, “The Case for Growth Centers” ITIF examined the place innovation jobs are discovered within the U.S. financial system, defining these as jobs that in industries which have a specified stage of R&D depth and that make use of a sure share of STEM employees. ITIF discovered that absolutely one-third of U.S. innovation jobs are concentrated in simply 14 U.S. counties, and one-half in 40 counties.[51] This perception was half of the inspiration behind Congressional creation of the Economic Development Adminsitration’s (EDA) Regional Tech Hubs program. EDA has designated 31 Tech Hubs and in July 2024 launched $504 million in Implementation awards for 12 of the 31 designated Tech Hubs.[52]

Besides Congress not appropriating sufficient cash, this system was poorly carried out. The Biden administration allowed NSF and the Department of Commerce (together with the Department of War and the Small Business Administration) to develop their very own regional hub applications with no coordination, primarily spreading restricted reasou4ces far too broad and skinny. Moreover, many of the EDA awards are weak and doubtless to by no means grow to be self-sufficient hubs as soon as federal funding ends. The Trump administration ought to redo the competitors, however this time fund fewer facilities, make NSF and EDA develop a joint program, and make sure that winners may very well be self-sufficient and focused on what ITIF calls “national power” industries (as subsequently defined).

9a. What are the most important obstacles confronted by small and medium-sized manufacturing firms in adopting superior applied sciences to enhance effectivity and productiveness?

SMEs lag in adopting new applied sciences that may make them extra productive, particularly with regard to incorporating digital applied sciences.[53] SME producers typically lack the knowhow to implement superior applied sciences or are unsure concerning the worth proposition behind doing so. As famous beforehand, this is the reason it’s essential to describe discrete, particular manufacturing digitalization use circumstances and processes and to present benchmark evaluation instruments so SMEs can perceive the place they’re of their digital manufacturing journey. Another important problem pertains to the shortage of digital workforce abilities to implement digital manufacturing options.

SMEs typically lack the capital to spend money on productivity-enhancing applied sciences. This problem is amplified by stress from Original Equipment Manufacturers (OEMs) to reduce prices, which additional limits their potential to spend money on modernized capital gear. In reality, research estimate that the lack of small companies to spend money on gear and plant upgrades contributes to a stark 40 p.c productiveness hole with massive producers.[54] SMEs typically lack the out there capital to spend money on modernized plant and gear; for occasion, McKinsey analysis discovered that absolutely one-quarter of SMEs within the mid-Atlantic area lack the capital even to meet their weekly working-capital wants.[55] The OECD finds that entry to capital has typically been tighter for SMEs within the United States than in different OECD international locations ever because the Great Recession.[56]

Regarding this problem, federal capital help (akin to by means of upfront grants or repayable loans) might assist them meet upfront funding prices (with the upgraded gear delivering important return on funding subsequently). This was the perception behind Congress allocating $50 million to the Department of Energy’s Office of Manufacturing and Supply Chain Resilience (MSRC) to be distributed to states for sensible manufacturing pilot implementation applications.

In 1988, President Ronald Reagan signed bipartisan Congressional laws within the Omnibus Trade and Competitiveness Act, which, amongst different initiatives, launched the Manufacturing Extension Partnership (MEP) program. Congress initially envisioned this system—which is managed by the Department of Commerce’s NIST and which operates in all 50 U.S. states in addition to Puerto Rico—as delivering experience on high quality manufacturing practices to America’s SMEs, however since then the remit of this system has broadened to be about enhancing the productiveness and technological efficiency of U.S. manufacturing. The MEP community consists of roughly 475 service places throughout its 51 facilities. NIST asserts that, in FY 2024, the MEP National Network helped producers obtain $15 billion in new and retained gross sales, $5 billion in new consumer investments, $2.6 billion in price financial savings and over 108,000 jobs created or retained.[57] Since 2000, the MEP National Network has labored with 77,409 producers, main to $60 billion in new gross sales and $26.2 billion in price financial savings, and has helped create and retain 1,456,889 jobs, in accordance to NIST.[58] Elsewhere, a report from Summit Consulting and the Upjohn Institute for Employment Research discovered that this system generated a monetary return of greater than 17:1 on the $175 million in federal funds it acquired in fiscal yr 2023.[59]

Unfortunately, the MEP program has been focused for zeroing-out because the first Trump administration and was one of the applications designated for elimination in the Project 2025 initiative.[60] Yet the MEP program performs an essential position in America’s SME producer help ecosystem, and whereas it might advantage important reforms, this system shouldn’t be wholesale terminated.

When MEP was established in 1982, it made sense to have a community of state-focused facilities working with producers in every state. But a state-by-state focus presents difficulties when fashionable manufacturing challenges are more and more horizontal in nature—e.g., synthetic intelligence, cybersecurity, manufacturing digitalization, provide chain integration, and so forth.—and it makes much less sense for every MEP heart to develop its personal capabilities in these areas independently. MEP ought to develop a centralized “Center of Excellence” to develop schooling/coaching/implementation modules relating to these cross-cutting manufacturing challenges and distribute them by means of the regional MEP supply system.

Here, it’s crucial that the MEP program works intently with the Manufacturing USA community. America’s 18 Institutes of Manufacturing Innovation—spanning manufacturing domains from bio-manufacturing, digital/automation, electronics, and vitality/atmosphere to supplies—needs to be considered as “the tip of the spear” for growing superior manufacturing product and course of applied sciences within the United States. But MEP needs to be the channel by means of which these novel manufacturing product/course of applied sciences get subtle to America’s SME producer base. As such, every Manufacturing USA Institute ought to have an ongoing MEP “embedded representative” hooked up to it, with a mandate to develop a technique for diffusing applied sciences being developed out of the Institutes throughout the MEP community.

Another avenue of MEP reform needs to be recognizing that, as a result of provide chains cross state boundaries, MEP wants many extra cross-state, sector-based MEP initiatives (e.g., autos within the U.S. Midwest and South, semiconductors within the Southwest). In different phrases, MEP ought to tackle extra of a supply-chain and sector-based focus. One can envision different regional/sectoral MEPs targeted on wooden/paper merchandise within the Northwest, semiconductors within the Southwest, medical units within the higher Midwest, maritime/shipbuilding within the Northeast, protection manufacturing in California or Texas, and so forth. If MEP departs from a predominantly state-based supply mannequin, it ought to reorient its method to a regional/industrial supply of SME companies with a higher provide chain orientation.

A major problem for the MEP program has been that MEP facilities typically undertake small tasks (common challenge dimension is about $15,000), so the engagements typically don’t show actually transformative for the shopper (partly as a result of MEP engagements typically aren’t on the CEO stage), and have a tendency to interact line managers or a enterprise unit. MEP wants to deal with transformation tasks with clients, one thing it might higher accomplish if it had longer-term, extra secure funding that permitted facilities to rent and retain extra subtle workers that may construct longer-term experience.

Another method to strengthen MEP can be to emphasize assignments not simply with the SME, but in addition their OEM clients, akin to by defining joint grants (matched by the bigger agency) for clients and suppliers that apply collectively. The bigger agency’s help would exhibit that it’s dedicated to these suppliers and believes these suppliers are viable and strategic. It would additionally ease a key drawback that small companies face: offering them with essential demand-side certainty would vastly cut back the hazard they face in making investments in new merchandise or processes since they don’t have the earnings to place bets that may not repay.

For occasion, ITIF has lengthy argued the United States wants to introduce mechanisms to encourage OEMs to take extra possession of manufacturing provide chain digitalization. Large U.S. producers have tended to hold their suppliers at arm’s size, too typically treating them on a transactional foundation with price because the principal concern. But because the McKinsey Global Institute notes, “this approach can affect the bottom line. One McKinsey study found that inefficiencies in OEM-supplier interactions add up to roughly 5 percent of development, tooling, and product costs in the auto industry.”[61] Put merely, U.S. OEMs want to take extra possession for driving digital transformation inside their provide chains. To this finish, ITIF has beforehand argued that the U.S. authorities ought to present incentives for U.S. OEMs to assist 10,000 SMEs to grow to be smart-manufacturing enabled inside 10 years.[62]

Another potential OEM-SME partnership alternative pertains to accumulating shared information that would assist AI-based programs akin to digital twins function extra successfully. Manufacturing generates extra information than some other sector of the financial system, but few firms are harnessing it.[63] Yet AI programs grow to be simpler once they have extra information to prepare on, akin to if they’ve information concerning the working efficiency of manufacturing gear or machine instruments that they will study from to predict failure modes prematurely (i.e., predictive upkeep). Many firms personal related or the identical machines or instruments, but the info is siloed internally and others can’t study from it. NIST could lead on a voluntary initiative the place firms would share anonymized information into a shared information lake that would create new information units towards which novel AI algorithms may very well be developed.

10. What are examples of public-private partnership fashions (on the worldwide, nationwide, state, and/or native stage) that may very well be expanded to facilitate manufacturing expertise improvement, expertise transition to market, and workforce improvement?

Two applications are right here value highlighting and concentrating on for growth. The Trump administration ought to work with Congress to develop manufacturing-focused Engineering Research Center (ERC) applications. The U.S. National Science Foundation’s (NSF) Engineering Research Center program helps a community of 17 strategic university-industry partnerships that pursue high-risk, high-payoff analysis throughout nearly your entire spectrum of expertise fields—together with superior manufacturing, biotechnology, clear vitality and sustainability, microelectronics and info expertise.[64] Since 1985, NSF has funded 83 ERCs which have led to greater than 1,400 invention licenses, 920 patents, and 250 spinoff firms.[65]

Unfortunately, NSF at present solely helps three ERCs explicitly targeted on superior manufacturing actions: the NSF ERC for Cell Manufacturing Technologies (CMaT), the NSF ERC for Hybrid Autonomous Manufacturing Moving from Evolution to Revolution (ERC-HAMMER), and the NSF Engineering Research Center for Transformation of American Rubber by means of Domestic Innovation for Supply Security (NSF TARDISS ERC).[66] In August 2024, NSF introduced a five-year funding of $104 million, with a potential 10-year funding of up to $208 million, in 4 new ERCs, together with a new one targeted on biomanufacturing-empowered decarbonization.[67] This represents progress, nevertheless it’s not sufficient; the administration ought to work with Congress to guarantee not less than $150 million in annual funding for the NSF ERC program, supporting each present and new manufacturing-focused ERCs. Further, the ERCs needs to be required to have their federal funding matched not less than half by {industry} in money.

NSF ought to have extra of its finances allotted to its Technology, Innovation, and Partnership (TIP) program, which focuses on translating use-inspired analysis into societal impression. An important side of the TIP program is that it requires each challenge it funds to have an {industry} associate. Despite minimal appropriated assets, in simply two years TIP has launched regional innovation applications, funded workforce improvement, improved U.S. competitiveness in two key applied sciences, and established partnerships with federal companies and allies like India and Japan. Yet this system’s workforce has shrunk 45 p.c because the begin of the yr due to cuts made by the Department of Government Efficiency and a hiring freeze. The Trump administration ought to work with Congress to increase TIP appropriations to not less than $1 billion yearly.[68]

The Industry University Cooperative Research (IUCRC) program forges partnerships between universities and {industry}, that includes industrially related elementary analysis, industrial help of and collaboration in analysis and schooling, and direct switch of university-developed concepts, analysis outcomes, and expertise to U.S. {industry} to enhance its aggressive posture in international markets.[69] NSF at present operates 9 IUCRCs targeted on superior manufacturing innovation, with the most recent one, the Center for Integrated Material Science and Engineering of Pharmaceutical Products (CIMSEPP) launched in 2022.[70] As with the ERC program, the United States might get extra out of the IUCRC program to help U.S. superior manufacturing. The Trump administration ought to work with Congress to present annual funding for the IUCRC program that helps not less than 15 ongoing advanced-manufacturing targeted IUCRCs.

Innovation vouchers can function efficient devices to convey small companies nearer to native universities to collaborate on proof of idea testing or expertise improvement. For the previous a number of years, the National Renewable Energy Laboratory (NREL), Sandia National Laboratories (SNL), and Pacific Northwest National Laboratory (PNNL) have offered technical help to the recipients of Department of Energy (DOE) -funded voucher applications, particularly American-Made Challenges (AMC), the Incubator Program, and the Small Business Vouchers Program. This effort needs to be absolutely constructed out into a nationwide program throughout the clear vitality targeted federal labs to drive sturdy relationships between entrepreneurs and the nationwide labs to speed up the roll-out of new applied sciences in U.S. clear vitality sectors akin to electrical automobile (EV) batteries and photo voltaic cells.[71]And, right here, provided that the United States is trailing so badly in EV battery expertise to China, the Trump administration ought to launch such a “BatteryShot Initiative” with the aim of producing a battery with a whole system price of lower than $200/kWh and a vary of not less than 1,000 miles per cost.[72]

11. The present 2022–2026 National Strategy for Advanced Manufacturing has three top-level targets, every with targets and priorities: (1) Develop and implement superior manufacturing applied sciences; (2) Grow the superior manufacturing workforce; and (3) Build resilience into manufacturing provide chains and ecosystems.

11a. Are these targets applicable for the subsequent 4–5 years? Why or why not?

These are applicable beginning targets, however the foremost aim of the National Advanced Manufacturing Strategy over the upcoming five-year interval needs to be documented enhancements within the well being of what ITIF calls America’s “national power” industries.

The stark actuality is that the type of reforms and changes proposed above will assist, however we shouldn’t idiot ourselves that they may cease China from dominating superior manufacturing. To cease that America wants far more and that may price cash and political capital. Congress wants to not less than triple the R&D tax credit score, one thing from which producers are the principal beneficiary. We want a new and massive supply of affected person capital to enable producers to spend money on equipment. We want to block Chinese imports of superior manufacturing items when they’re unfairly produced and traded. We want the DOW to considerably develop its efforts past protection companies per se to a broad array of twin use companies and industries.

In quick, U.S. manufacturing technique ought to concern itself not with non-strategic industries (i.e., baseball gloves and ballpoint pens) however on enabling industries, dual-use industries, and protection industries, which collectively represent nationwide energy industries.[73] (See determine 1.)

Figure 1: Industrial energy scale

At one finish of the continuum are protection industries. Clearly industries akin to ammunition, guided missiles, army plane and ships, tanks, drones, protection satellites, and others are strategic. Not having world class innovation and manufacturing capabilities in these industries means a weakened army functionality. Policymakers throughout the aisle typically agree that these industries are strategic and that market forces alone is not going to produce the wanted outcomes.

At the opposite finish of the spectrum are industries during which the United States has no actual strategic pursuits. These embrace furnishings, espresso and tea manufacturing, bicycles, carpet and rug mills, window and door manufacturing, plastic bottle manufacturing, wind turbine manufacturing, garden and backyard gear, sporting items, jewellery, caskets, toys, toiletries, trainers, and so forth. If worst got here to worst and our adversaries (e.g., China) gained dominance in any of these industries and determined to reduce America off, America would survive—partly, as a result of none of these are important to the operating of the U.S. financial system, as many are closing items that may inconvenience customers however wouldn’t cripple any industries, and additionally as a result of, most often, home manufacturing may very well be began or expanded comparatively simply as a result of none of these merchandise are all that technological complicated from both a product or course of concern and the limitations to entry are comparatively low.

Next to protection industries dual-use industries are important to American energy. Losing aerospace, prescription drugs, chemical compounds, semiconductors, shows, superior software program, fiber optic cable, telecom gear, machine instruments, motors, measuring units, and different dual-use sectors would give our adversaries unimaginable leverage over America. Just the menace to reduce these off (assuming that they’ve additionally deindustrialized our allies in these sectors) would instantly convey U.S. policymakers to the bargaining desk. National energy industries have a tendency to additionally want international scale so as to full. Moreover, many are intermediate items akin to semiconductors and chemical compounds, the place a cutoff would cripple many different industries. Finally, these industries are onerous to get up as soon as they’re misplaced as a result of of the complexity of the manufacturing course of, product information, and the significance of the economic commons that help them. In different phrases, limitations to entry are excessive and, if misplaced, can be very tough and costly to reconstitute.

Finally, there are enabling industries. These are industries whereby, if the United States have been reduce off, the speedy results on army readiness can be small. And the U.S. financial system might survive for not less than a whereas with out manufacturing. America might survive for a few years with out an auto sector, as we’d all simply drive vehicles longer. But as a result of of the character of these industries—together with expertise improvement, course of innovation, abilities, and supporting establishments—their loss would hurt each dual-use and protection industries. That is as a result of enabling industries contribute to the economic commons that help dual-use protection industries. A severely weakened motorcar sector would weaken the tank and army automobile ecosystem. Similarly, a weakened industrial shipbuilding sector has weakened army shipbuilding. A weakened client electronics sector weakens army electronics.

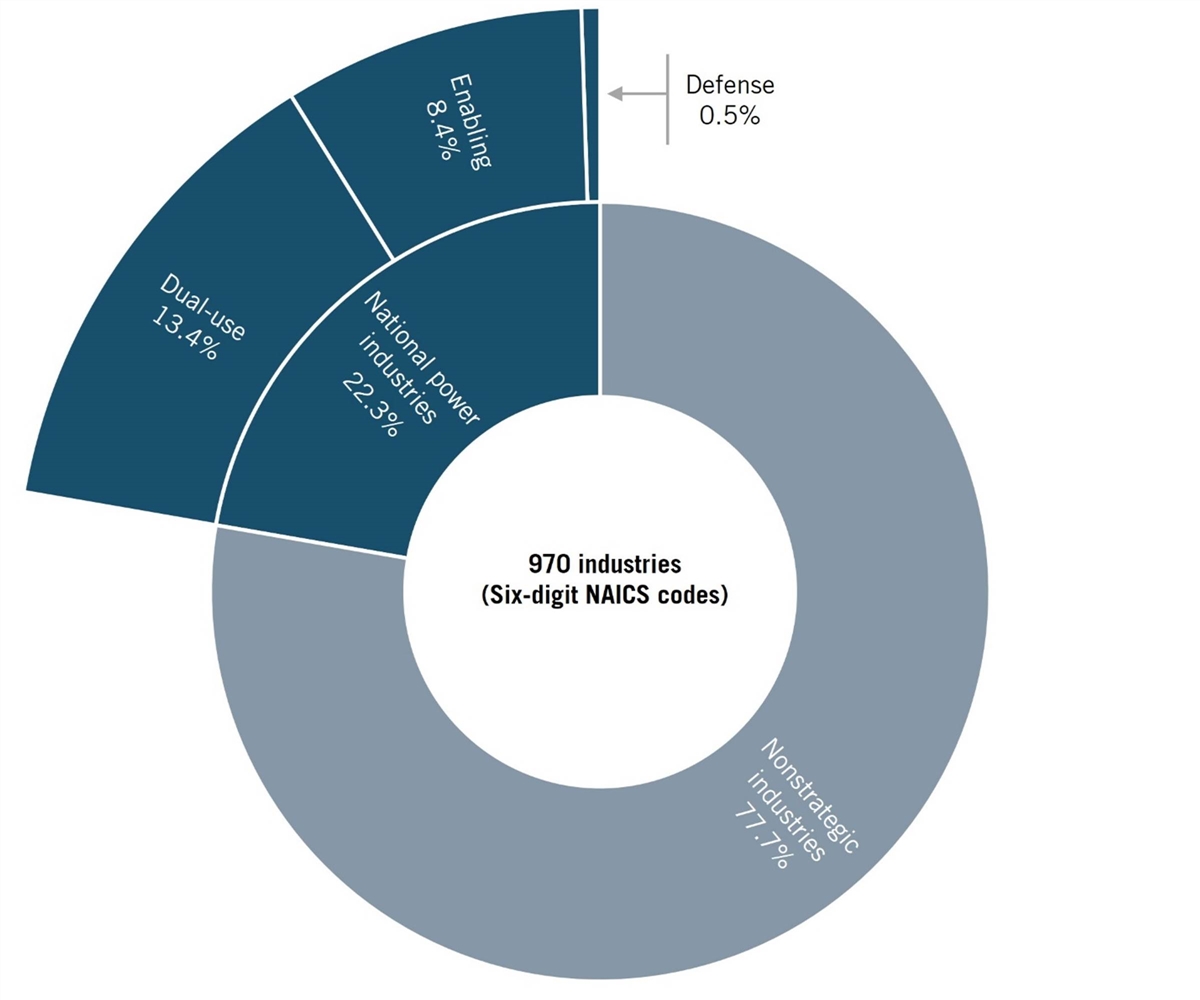

The industries that ITIF defines as nationwide energy industries characterize about 22 p.c of the full 970 industries delineated by the North American Industry Classification System (NAICS). Of these 22 p.c, 13 p.c are dual-use industries, 8 p.c are enabling, and simply 0.5 p.c are protection industries. (See determine 2.) In phrases of employment, simply 9.5 p.c of employees have been employed in energy industries, with 6.4 p.c employed in dual-use industries, 2.9 p.c in enabling industries, and the remaining 0.2 p.c employed in protection industries.[74]

An evaluation of a number of quantitative indicators of manufacturing inputs and outputs signifies that dual-use and enabling manufacturing industries have declined greater than nonstrategic and protection industries over the previous a number of years, from 2007 to 2022.

Figure 2: Breakdown of six-digit NAICS industries in accordance to ITIF’s nationwide energy {industry} typology

Dual-use and enabling industries have seen the steepest declines in employment among the many 4 classifications, with declines of 17 p.c and 19 p.c, respectively, in contrast to a 10 p.c decline in nonstrategic and protection industries. Additionally, capital funding in productivity-enhancing capital, akin to equipment and gear, fell by 34 p.c in enabling industries, whereas dual-use industries noticed no change, and nonstrategic and protection industries elevated funding by 7 p.c and 32 p.c, respectively.[75]

Nominal worth added grew throughout all classifications, but progress was weakest among the many core manufacturing base of enabling and dual-use industries. Nonstrategic industries noticed the very best progress of 26 p.c, adopted by protection industries (16 p.c), then enabling and dual-use industries, which grew by simply 11 p.c and 4 p.c, respectively.[76] When contemplating inflation, which has grown roughly 41 p.c economy-wide, worth added in enabling and dual-use industries declined considerably.[77]

The decline in enabling and dual-use {industry} output signifies a hollowing out of the U.S. industrial base, and the results of this are extreme. These industries are most important to U.S. nationwide safety and help home provide chains and nationwide energy, and they’re shedding floor to worldwide rivals, particularly China. China has adopted a predictable playbook throughout {industry} after {industry}, with important state monetary backing, compelled expertise switch, and IP theft, leaving American companies unable to compete and contributing to the decline of U.S. superior manufacturing. To fight this decline and push again towards Chinese financial mercantilism, the United States should implement a nationwide energy {industry} technique during which essentially the most important industries for nationwide energy are prioritized in policymaking. As famous beforehand, step one in attaining that is the crafting of industry-specific methods.[78]

While common industrial help, akin to R&D credit and full expensing for capital gear, are useful instruments in industrial improvement, their impacts are restricted. All nationwide energy industries differ of their construction, key gamers, aggressive forces, and technological wants, which means every requires curated, individualized strategic help to assist companies within the United States compete in international markets. Critical industries needs to be highlighted and methods developed, together with a nationwide semiconductor technique, a nationwide aerospace technique, a nationwide robotics technique, and extra. Creating these methods would require in-depth {industry} analysis, figuring out distinctive strengths and weaknesses, alternatives, and threats in every {industry}, and analyzing how federal, state, and native coverage help will impression international energy and competitiveness.[79]

The Information Technology and Innovation Foundation commends the Trump administration for working to develop an up-to-date, coherent National Strategic Plan for Advanced Manufacturing. The success of this effort shall be very important to enhancing the worldwide competitiveness of U.S. superior manufacturing over the approaching decade.

Thank you for your consideration.

[14]. Kagermann et al., Industrie 4.0 in a Global Context: Strategies for Cooperating with International Partners.

[23]. B. Graham, “Patent Bill Seeks Shift to Bolster Innovation,” The Washington Post, April 8, 1978; Ashley J. Stevens et al., “The Role of Public-Sector Research in the Discovery of Drugs and Vaccines” The New England Journal of Medicine Vol. 364, Issue 6 (February 2011): 1, https://www.nejm.org/doi/full/10.1056/NEJMsa1008268.

[42]. Ezell and Atkinson, “Fifty Ways to Leave Your Competitiveness Woes Behind: A National Traded-Sector Competitiveness Strategy.”

[46]. Ezell and Atkinson, “Fifty Ways to Leave Your Competitiveness Woes Behind: A National Traded-Sector Competitiveness Strategy.”

[55]. Phone dialog with Sree Ramaswamy, April 27, 2018.

[56]. Ramaswamy et al., “Making It In America: Revitalizing U.S. Manufacturing,” 56.

[61]. Ramaswamy et al., “Making It In America: Revitalizing U.S. Manufacturing,” 56.

[62]. Ezell et al., “Manufacturing Digitalization: Extent of Adoption and Recommendations for Increasing Penetration in Korea and the U.S.,” 44.

[69]. U.S. National Science Foundation, “Accelerating Impact Through Partnerships: Industry–University Cooperative Research Centers,” https://iucrc.nsf.gov/.

[78]. Atkinson, “Marshaling National Power Industries to Preserve America’s Strength and Thwart China’s Bid for Global Dominance.”