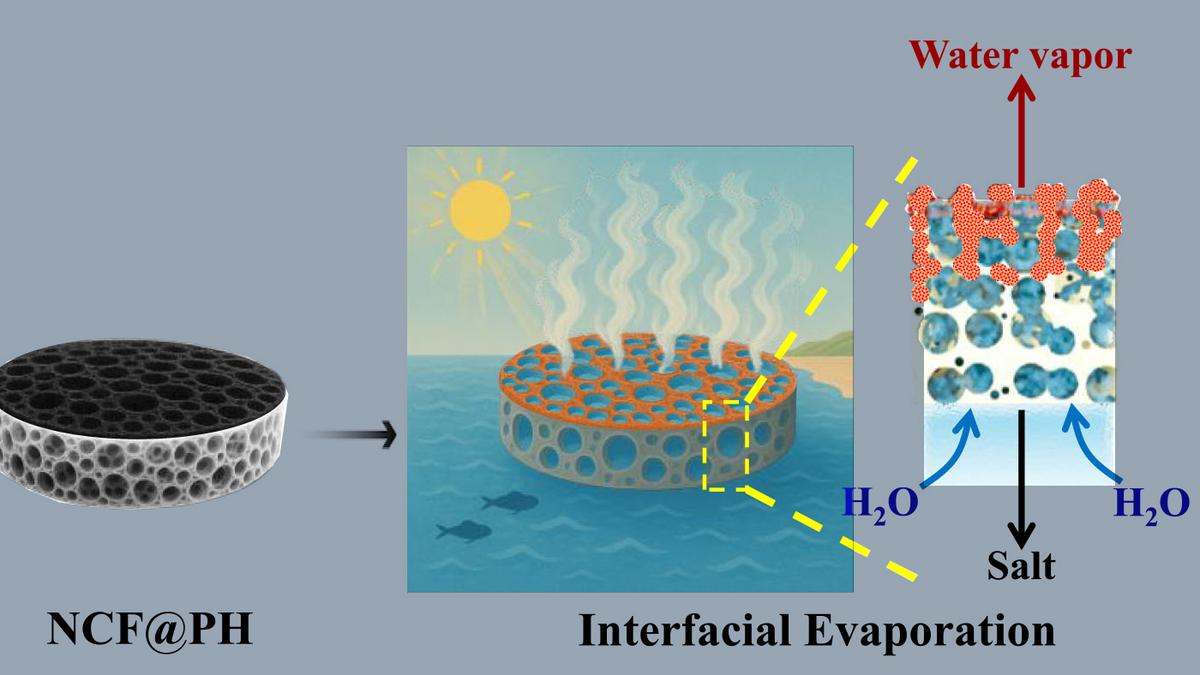

JANUS-FACED FLOATING FILM: Schematic illustration of the steps concerned in the fabrication of an NCF@PH photo voltaic–thermal interfacial evaporator

A bunch of researchers have reported a breakthrough in desalination that might dramatically change the economics of manufacturing freshwater from the ocean and brackish water.

The innovation centres on an engineered materials — an ultra-thin floating movie referred to as NCF@PH, described as “Janus-faced” as a result of it has two distinct sides, just like the Roman god. One aspect accommodates nano-carbon florets (NCF) — nano-carbon buildings formed like tiny marigold flowers — that are optimised to entice daylight and minimise reflection. The different aspect is product of a particular porous polymer (porosity-tuned excessive inner section emulsion polymer).

Imagine a tank of seawater lined by a glass sheet. The NCF@PH movie floats on the water, masking it. When daylight strikes the system, the NCF on the sun-facing aspect absorbs massive quantities of sunshine.

The underside of the movie — in contact with the water — acts as a scaffold for the NCF coating. The NCF heats the water, inflicting it to evaporate. Water vapour passes by way of the movie into the area between the movie and the glass lid, from the place it’s directed to a Peltier cooler for condensation.

Evaporation increase

Researchers from the departments of chemistry and mechanical engineering at IIT-Bombay collaborated with Monash University in Australia to construct a prototype system referred to as SunSpring. The core of the system is the NCF materials.

Two years in the past, Prof Subramaniam Chandramouli of IIT-Bombay, who’s a part of the SunSpring workforce, had synthesised these nano-carbon florets using silica “moulds”. As reported in Quantum on February 10, 2023, he demonstrated that when coated on porcelain or copper and uncovered to daylight, the fabric may warmth as much as 160 levels C inside minutes.

In a latest paper in Advanced Science, the researchers describe how the NCF is built-in onto a porosity-engineered, hydrophobic polymer to create an ultra-thin (200 micrometre), unsinkable solar-thermal evaporator. This design boosts the water evaporation fee to 4.5–6.5 kg per sqm per hour, in contrast with 1.29 kg in standard methods.

As a end result, SunSpring can produce 18 litres of freshwater per sqm per day — greater than double the 7 litres typical of ordinary evaporation-based desalination methods. The mixture of NCF and polymer channels the solar-thermal vitality to the water for evaporation and prevents warmth loss to the surroundings.

Tests at IIT-Bombay confirmed that SunSpring may convert seawater containing 35,000 ppm of salt into freshwater with lower than 10 ppm of salt. According to Mohammed Aslam and Amrutha Suresh, the lead authors of the work, the machine can run constantly for as much as 225 hours.

Efficient condensation

A serious enchancment is in the way in which SunSpring handles condensation. In standard photo voltaic stills, the identical glass floor is used each to confess daylight and to condense vapour. Once condensation begins, droplets type on the glass, scattering gentle and decreasing heating — and due to this fact decreasing effectivity.

SunSpring avoids this drawback by separating the evaporation and condensation chambers. The condensation floor is a Peltier cooler, a thermoelectric machine that turns into chilly on one aspect and scorching on the opposite when powered. “An important aspect of the SunSpring design lies in the decoupling of the sunlight-admitting surface from the water-collection surface,” the paper notes. In addition, salt accumulates solely on the water-facing underside of the movie, from the place it may be simply washed away.

The analysis is supported by The Green Energy and Sustainability Hub at IIT-Bombay and Anusandhan National Research Foundatuon (ANRF).

Cost issue

Prof Chandramouli estimates that SunSpring can produce freshwater at thrice the price of a typical RO system. However, prices will fall when the NCF@PH movie is produced at an industrial scale.

The workforce, after two years of growth work, now plans to arrange a pilot plant in the Rann of Kutch, Gujarat, the place groundwater salinity is extraordinarily excessive and impacts native well being. The pilot, to be put in in a college, will present 300 litres of pure water per day for the youngsters.

More Like This

Published on November 17, 2025